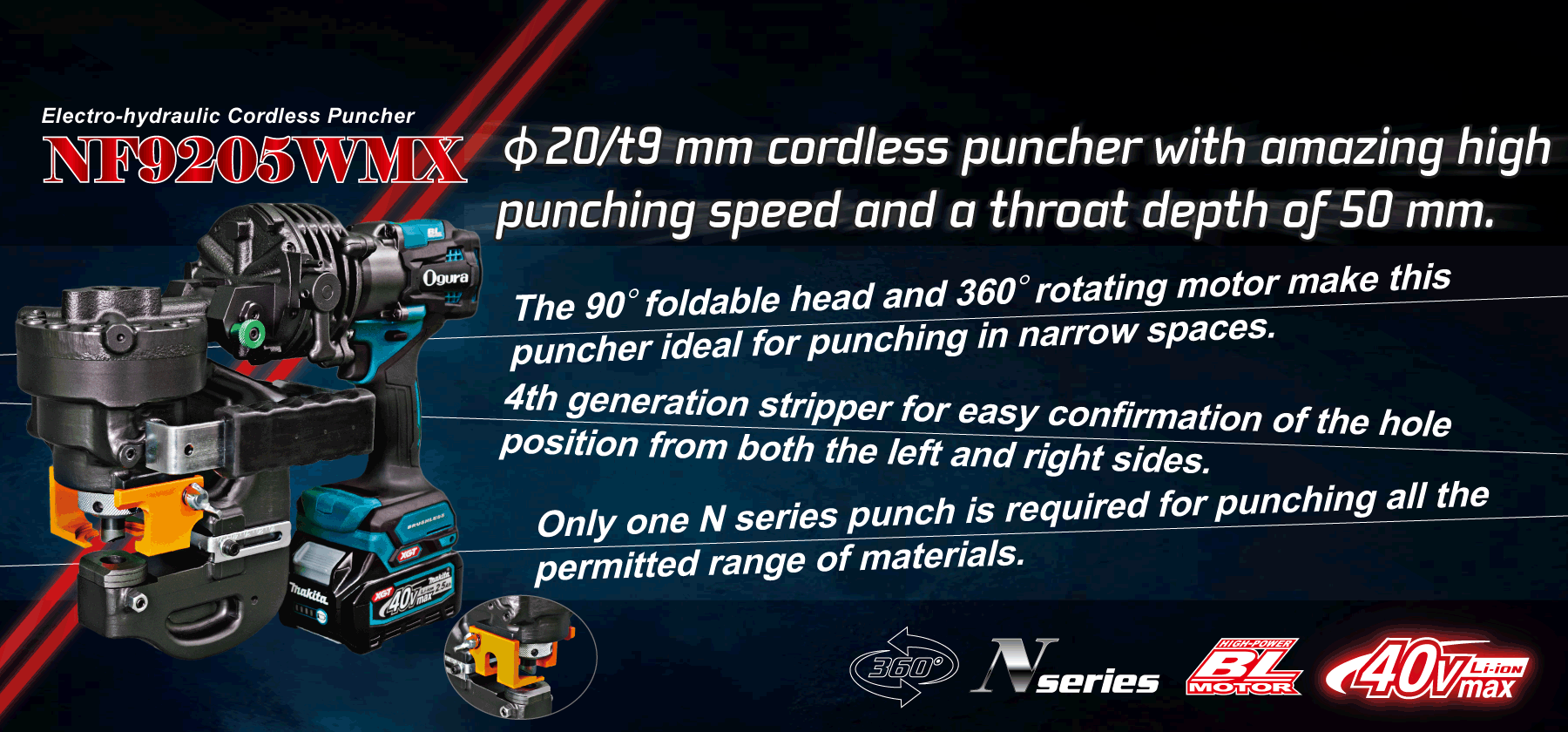

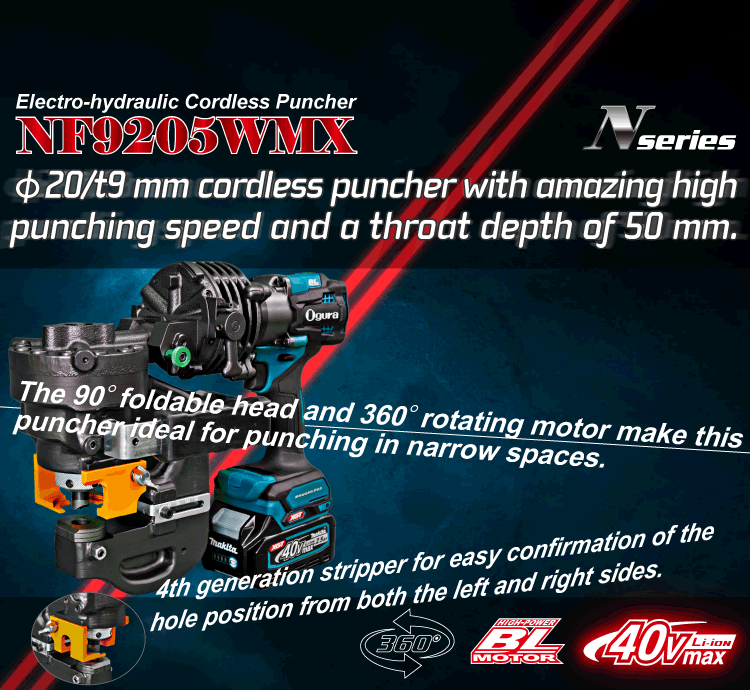

FEATURESNF9205WMX

- - Punching up to the maximum throat depth of 50mm possible without the need to change or remove the slide stopper.

- - Very fast punching speed for cordless puncher 3.5 seconds※1 for thickness 9mm.

- - 4th generation stripper for easy confirmation of the hole position from both the left and right sides.

- - The 90°foldable head※2 and 360°rotating motor makes this puncher ideal for use in narrow spaces.

- - 40V max battery has water and dust-resistant triple layer structure and an enhanced terminal structure are engineered to protect against water and dust for any job site condition.※3

- - According to optimal power supply + optimal charging = “smart system” significantly increases battery life (compared to conventional models).

- - On site portability for maximum freedom of movement with Li-ion battery motor.

- - Hole puncher is specifically designed to provide high quality holes quickly and efficiently.

- ※1 Based on our test value. The test value except for returning speed. Punching speed varies depending on cutting conditions.

- ※2 Can be fixed at 0 degree and 90 degrees using the head lock.

- ※3 This tool is designed to be less susceptible to dirt and moisture, but we do not guarantee that it will not break down due to dirt and moisture.

- "N" series is▲▲▲▲

- The new "N" series punchers are double acting with a new designed punch holder for longer life. The "N" series punch has also been redesigned so that only one punch is required to punch the range of materials: mild steel, stainless steel, angle iron and channel steel. The center of the punch has been made wider for easier positioning.

- - Both punching and retracting are completed by hydraulic power. This solves the "punch jammed" problem and allows uninterrupted and faster work.

- - Following a review by our customers, we changed the design of the die, punch & punch holder to make them more durable and to make the setting of the punch & die easier.

- - Only one die for flat bar, angle steel and channel flange is required. It is not necessary to change the die when punching different materials or thicknesses.

- ※Thinner material (t2-3.2mm) may have some burrs or deformation.

- - New punch design makes it easier to confirm the hole position.

SPECIFICATIONSNF9205WMX

| Motor | D.C. 36V (40V max) |

| Weight | 12.7 kg / 28.0 lbs (with 2.5Ah battery) |

| Dimensions | 423 (L) x 138 (W) x 345 (H) mm 16.65 x 5.43 x 13.58 in |

| Max. Throat Depth | 50 mm / 1.97 in |

| Hole Shape | Round / Oblong |

| Max. Hole Size | Mild steel (65,000 psi): Φ20/t9 mm |

| Stainless steel (89,000 psi): Φ20/t6 mm | |

| Standard Accessories | punch Φ14 mm, die SB14, tommy bar, spanner (8 × 10 mm), hex wrenches, carrying case, grip |

| Option | work stand |

OTHER INFORMATIONNF9205WMX

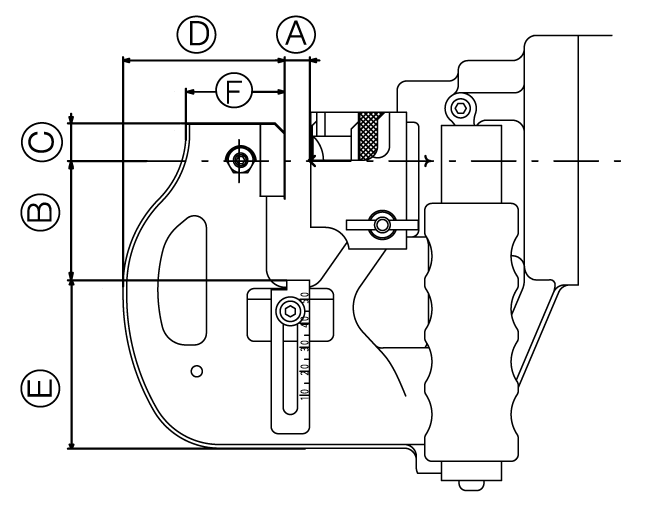

- ■Materials Dimensions [unit: mm]

Flat Bar

Max. 100 x t9

(center punching)Angle Steel

Min. 40 x 40

Max. 75 x 75 x t9

Max. 80 x 80Channel Flange

Min. 75 x 40 x t7

Max. 125 x 65 x t8H-steel

Min. 100 x 100 x t8

Max. 300 x 150 x t9- ■Punching Throat

A: 10 mm

B: 50 mm

C: 15 mm

D: 68 mm

E: 71 mm

F: 42 mm

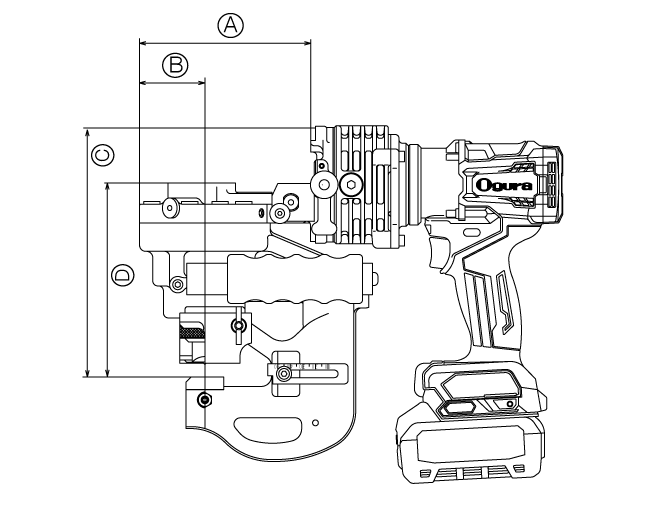

- ■Other Dimensions

A: 137 mm

B: 52.5 mm

C: 205 mm

D: 155 mm

Punch & Die TABLENF9205WMX

■Round Punch & Die [unit: mm]

■Oblong Punch & Die [unit: mm]

■Vertical Oblong Punch & Die [unit: mm]

| Round Punch | Round Die | Mild Steel | Channel Flange | Stainless Steel |

|---|---|---|---|---|

| 6 | SB6 | t2 - t4 | - | t3 - t4 |

| 6.5 | SB6.5 | t2 - t6 | - | t3 - t4 |

| 8 | SB8 | t2 - t6 | - | t3 - t4 |

| 8.5 | SB8.5 | t2 - t6 | - | t3 - t4 |

| 10 | SB10 | t2 - t6 | t8 | t3 - t4 |

| 11 | SB11 | t2 - t9 | t8 | t3 - t6 |

| 12 | SB12 | t2 - t9 | t8 | t3 - t6 |

| 13 | SB13 | t2 - t9 | t8 | t3 - t6 |

| 14 | SB14 | t2 - t9 | t8 | t3 - t6 |

| 15 | SB15 | t2 - t9 | t8 | t3 - t6 |

| 16 | SB16 | t2 - t9 | t8 | t3 - t6 |

| 18 | SB18 | t2 - t9 | t8 | t3 - t6 |

| 19 | SB19 | t2 - t9 | t8 | t3 - t6 |

| 20 | SB20 | t2 - t9 | t8 | t3 - t6 |

| Oblong Punch | Oblong Die | Mild Steel | Channel Flange | Stainless Steel |

|---|---|---|---|---|

| 6.5×10 | 6.5×10B | t2 - t6 | - | t3 - t4 |

| 6.5×13 | 6.5×13B | t2 - t6 | - | t3 - t4 |

| 8.5×13 | 8.5×13B | t2 - t6 | - | t3 - t4 |

| 8.5×17 | 8.5×17B | t2 - t6 | - | t3 - t4 |

| 9×13.5 | 9×13.5B | t2 - t6 | - | t3 - t4 |

| 9×18 | 9×18B | t2 - t6 | - | t3 - t4 |

| 10×15 | 10×15B | t2 - t8 | t8 | t3 - t6 |

| 10×20 | 10×20B | t2 - t8 | t8 | t3 - t6 |

| 11×16.5 | 11×16.5B | t2 - t9 | t8 | t3 - t6 |

| 12×18 | 12×18B | t2 - t9 | t8 | t3 - t6 |

| 13×19.5 | 13×19.5B | t2 - t9 | t8 | t3 - t6 |

| 14×21 | 14×21B | t2 - t9 | t8 | t3 - t6 |

| 15×21 | 15×21B | t2 - t9 | t8 | t3 - t6 |

| Vertical Oblong Punch | Vertical Oblong Die | Mild Steel | Channel Flange | Stainless Steel |

|---|---|---|---|---|

| TN12×20 | TN12×20B | t2 - t9 | t8 | t3 - t6 |

| TN14×20 | TN14×20B | t2 - t9 | t8 | t3 - t6 |